What is an electric motor?

An electric car motor works using a physical process developed at the end of the 19th century. This consists of using a current to create a magnetic field at the “stator”, fixed part of the machine whose displacement sets the “rotor”, a rotating part in motion. We’ll take a closer look at these two parts, and more, further down.

The principle of an electric motor

What’s the difference between an engine and a motor? The two words are often used interchangeably. It’s important, therefore, to differentiate them right from the start. Despite being employed as almost synonymous nowadays, when it comes to the automotive industry, a “motor” refers to a machine that converts energy into mechanical energy, and therefore motion, while an “engine” does the same thing, but specifically using thermal energy. When talking about converting thermal energy into mechanical energy, we therefore mean combustion —not electric.

In other words, an engine is a type of motor. But a motor is not necessarily an engine. With electric vehicles, because the mechanical energy is created from electricity, we use the word “motor” to describe the device that makes the electric vehicle move (aka traction).

How does an electric car motor work inside an EV?

Now that we know that we’re talking motors, not engines, how does a motor work inside an electric vehicle?

These days electric motors can be found in numerous everyday devices. Those that use direct current (DC) motors have quite basic functions. The motor is connected directly to an energy source and its rotation speed depends directly on the intensity of the current. While easy to produce, these electric motors don’t meet the power, reliability or size requirements of an electric vehicle, although you may find them powering the windshield wipers, windows and other smaller mechanisms inside the car.

The stator and the rotor

If you want to understand how an electric vehicle works, you need to be familiar with the physical elements of its electric motor. And it starts with understanding the principles of its two major parts: the stator and the rotor. The difference between the two is easy to remember: the stator is static, while the rotor rotates. In a motor, the stator uses energy to create a magnetic field that then turns the rotor.

So how does a motor work when it comes to powering an electric vehicle? For this we must turn to alternating current (AC) motors, which require the use of a conversion circuit to transform the direct current (DC) supplied by the battery. Let’s take a closer look at the two different kinds of current.

Powering an electric vehicle: AC vs. DC

First things first, if you want to understand how an electric car motor works, you need to know the difference between AC and DC (electron currents).

Electricity moves through a conductor in two ways. Alternating current (AC) describes an electric current in which the electrons periodically change direction. Direct current (DC), as its name suggests, flows in a single direction.

The battery in an electric car functions using direct current. But, when it comes to the main motor of the electric vehicle (which provides traction to the vehicle), this DC energy must be transformed into AC via an inverter.

So what happens once this energy reaches the motor? It depends on whether the vehicle uses a synchronous or asynchronous motor.

Types of electric motor

There exist two types of alternating current motors in the automobile industry: synchronous and asynchronous motors. When it comes to an electric vehicle, synchronous and asynchronous motors each have their own strengths — one is not necessarily “better” than the other.

Synchronous and asynchronous motors

An asynchronous motor, also called an induction motor, relies on the electric-powered stator to generate a rotating magnetic field. This then pulls the rotor into an endless chase, as if it were trying to catch up with the magnetic field without ever succeeding. An asynchronous motor is often used in electric vehicles that are largely used for driving at elevated speeds for long periods of time.

In a synchronous motor, the rotor acts as an electromagnet itself, actively participating in the creation of the magnetic field. Its rotation speed is thus directly proportional to the frequency of the current that powers the motor. This makes a synchronous motor ideal for urban driving, which typically requires regular stopping and starting at low speeds.

Both synchronous and asynchronous motors work in a reverse manner, meaning they can convert mechanical energy into electricity during deceleration. This is the principle of regenerative braking, which derives from the alternator.

Parts of electric motors

Let’s now take a closer look at some of the different parts found in an electric vehicle’s motor: from electric motor magnets or Externally Excited Synchronous Motors (EESM) to the powertrain unit in general.

Permanent magnets

Some synchronous motors use a permanent magnet motor for the rotor. These permanent magnets are embedded into the steel rotor, creating a constant magnetic field. A permanent electric motor magnet has the advantage of operating without a power supply but requires the use of metals or alloys such as neodymium or dysprosium. These “rare earths” are ferromagnetic, meaning they can be magnetized to become permanent magnets. They are used for multiple industrial purposes: from wind turbine generators, cordless tools and headphones, to bicycle dynamos and… traction motors for certain electric vehicles!

The problem is that the prices of these “rare earths” are very volatile. Despite their name, they aren’t necessarily that rare, in fact, but are found almost exclusively in China, which therefore has a quasi-monopoly on their production, sale and distribution. This explains why manufacturers have been working hard to find alternative solutions for electric vehicle motors.

Externally Excited Synchronous Motors

One of these solutions, chosen by Renault for ZOE and for the Twingo, Kangoo and Mégane E-Tech electric, is to manufacture an electric motor magnet from a copper coil. This solution requires a more complex industrial process, but avoids supply problems, while preserving the excellent ratio between motor weight and torque generated.

Guillaume Faurie, Head of Engineering at Renault's Cléon plant, describes the complexity and ingenuity of the wound rotor electric motor: "Manufacturing an independently excited synchronous motor requires specific winding and impregnation processes. The constraints linked to product performance expectations, the objective of reducing the weight/power ratio and high production rates mean that we have to make effective use of the most advanced technologies to implement these processes."

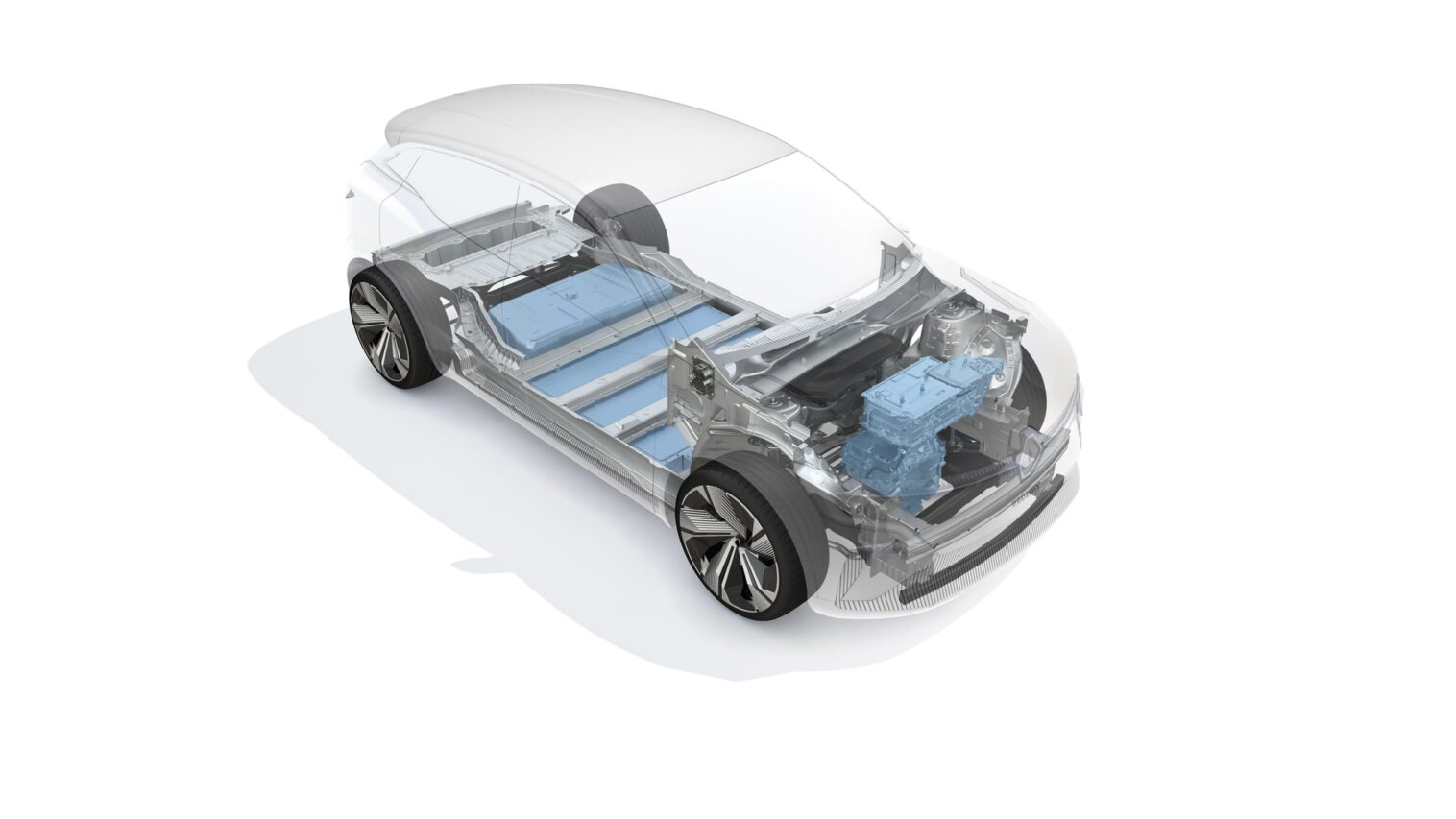

The electric powertrain

In an electric vehicle, the motor comprised of the rotor and the stator is part of a larger unit, the electric powertrain, an ensemble which makes the electric motor work.

The latter also includes electronic power controllers:

- The inverter, which regulates the motor's electrical energy to control torque and speed.

- The DCDC converter, which transforms the battery's DC voltage into 14V for the vehicle's on-board network.

- The on-board AC charger and C box for recharging the traction battery.

Finally, the unit includes the gearbox which adapts the rotation speed transmitted by the electric motor to the wheels.

Together, these elements make the electric motor work smoothly and efficiently. And the result? Your electric car is silent, reliable, less expensive and fun to drive!

Copyright : Pagecran